-

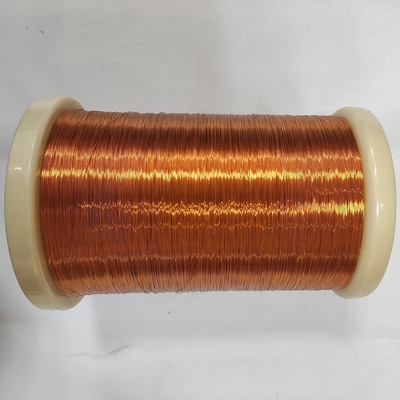

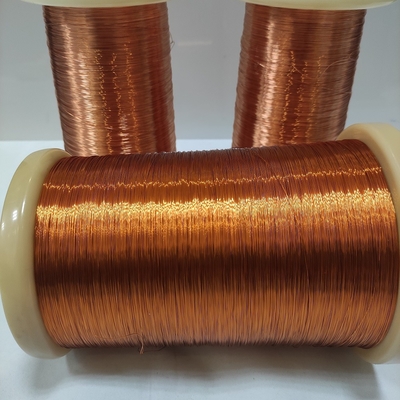

Copper Enameled Wire

-

Polyester Enameled Copper Wire

-

Polyesterimide Enameled Copper Wire

-

Self Bonding Wire

-

Polyurethane Enameled Copper Wire

-

Soldering Enameled Wire

-

Enameled Copper Clad Aluminum Wire

-

Enamelled Copper Winding Wire

-

Enamelled Round Copper Wire

-

Enameled Magnet Wire

-

Coated Magnet Wire

-

Voice Coil Wire

-

Sangho YiThanks for your help! We do many of evaluation and development. We need a bit more time to do this. When we finish our evaluation and development, then we will contact you.

Sangho YiThanks for your help! We do many of evaluation and development. We need a bit more time to do this. When we finish our evaluation and development, then we will contact you. -

Ian M BrownI received your response this morning (French time), and I have just read it. Thank you very, very much for your thorough response and for all the information you have given me in it.

Ian M BrownI received your response this morning (French time), and I have just read it. Thank you very, very much for your thorough response and for all the information you have given me in it. -

Svetlana PankratovaDear Leon, Happy Mid-Autumn Festival! As the moon rises, I wish you joy and happiness equal to its illumination.

Svetlana PankratovaDear Leon, Happy Mid-Autumn Festival! As the moon rises, I wish you joy and happiness equal to its illumination.

Insulation Polyester Enameled Copper Wire Varnished Plastic Spool Packing

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Order No. | 30011252190 | Product Name | Alcohol Self - Adhesive Enameled Wire |

|---|---|---|---|

| Conductor Diameter | 0.19mm | Color | Nature |

| Thermal Class | 155 | Applications | Voice Coil Motor |

| Insulation Material | PEW | Certification | ISO9001/ISO14001 /SGS/UL |

| High Light | Enamelled Copper Wire Self Adhesive,Plastic Spool Packing Enameled Copper Wire,Polyester Insulation Enameled Copper Wire |

||

Self Adhesive Enameled Copper Wire Insulation Polyester Varnished Copper Wire Plastic Spool

The industry standard of enameled wire is very important for winding industry. It directly affects winding speed, process and yield of winding machine. Before the winding operation, first of all to understand the parameters of enameled wire, and develop a feasible winding scheme, through the winding of products to do some adjustment, make the efficiency of winding machine and winding product quality to achieve the optimal combination.

The application of self-adhesive enameled wire in motor windings shows that the motor windings made by self-adhesive enameled wire can meet the technical requirements of the corresponding motor and have reliable performance.Self-adhesive enameled wire can be used to manufacture motor windings, which can omit the process of soaking, save energy, eliminate pollution and reduce labor intensity. It has good technical and economic effect and is worthy of popularization and application.

Specification:

| Model Number | PESVW-GB/155-0.19 | Place of Origin | Zhejiang,China |

| Conductor Material | Copper | Brand Name | CHINGCUNG |

| Conductor Diameter | 0.19mm | Feature | Excellent Film Adhesion |

| Bonding Method | Alcohol Soluble | Delivery Time | 3-10 work days |

| Thermal Class | 155 | Application | Motor Winding Wire |

| Film Grade | GB | Packing | Plastic Spool |

| Insulation | Polyester | OEM | Support |

FAQ:

Q1:Are you trading company or manufacturer ?

A:We are a manufacturer.

Q2:Are you a factory or a trader?

A:We are the factory, you are welcome to visit our factory.

Q3:How about your company’s annual production capacity?

A:Our Company’s annual production is about 1000 tons.

Q4:How about the quality?

A:We have the best professional engineer and strict QA and QC system. We have the experience of doing the self bonding enameled wires for more than 15 years.

Q5:Can you provide samples? Charge or free?

A:Yes, we can provide samples for payment, which can be sent to you by DHL express or FOB.